Custom-made glass products

CHROMA GLOBE produces high-quality laboratory and pharmaceutical packaging made of tubular glass and sells them worldwide. In addition to our own machines, firmly booked machine capacities at two other glass manufacturers provide the necessary production flexibility to be able to react quickly to unexpected demand.

At our production sites (100% Made in Germany) we manufacture glass products in small or large series. We generally divide into the following glass product groups:

Sample bottles and vials

Lockable independently, can stand independently

Micro Vials

Micro-Inserts

Design of the Neck

DIN Crimp Neck

Headspace Crimp Neck

Fire-Polished Neck

SPME Crimp Neck

Snap Ring Neck

Snap Cap Neck

Short Thread Neck ND9

Calibrated Neck

Precision Thread ND18

Screw Thread ND8, ND10

Screw Thread ND13, ND15

Screw Thread ND24

Design of the Vial Bottom

flat bottom

rounded bottom (HS-bottom)

round bottom

conical bottom

Solid glass bottom of a Microliter Vial with inner cone (High recovery)

Conical bottom (Maximum recovery Vial)

Dimensions

- Bottle body diameter (5mm – 42mm)

- Size of the bottle opening

- bottle height (up to 500mm)

Other specifications

- Glass material (clear/amber glass; 1st hydrolytic. Class)

- Bottle opening size (narrow-wide opening)

- With and without text field + filler mark

- Silanized (deactivated), special printing (logos)

Production of glass vials

The production can be divided into the following production steps:

01

Raw material: glass tubes

(usually Schott glass tubes of the 1st hydrol. class)

02

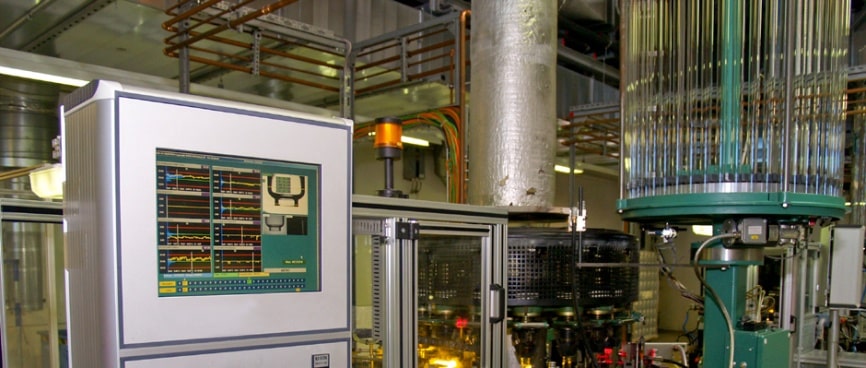

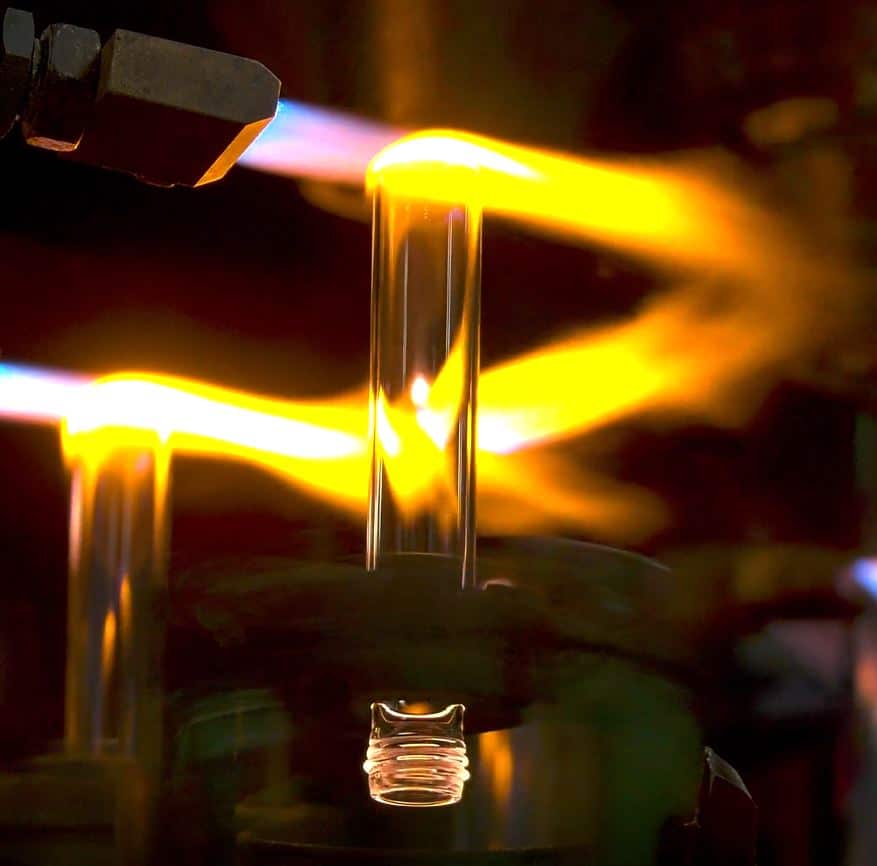

Forming the glass vials at different stations of the rotary machine

(bottom shaping, shoulder shaping, Neck shaping)

03

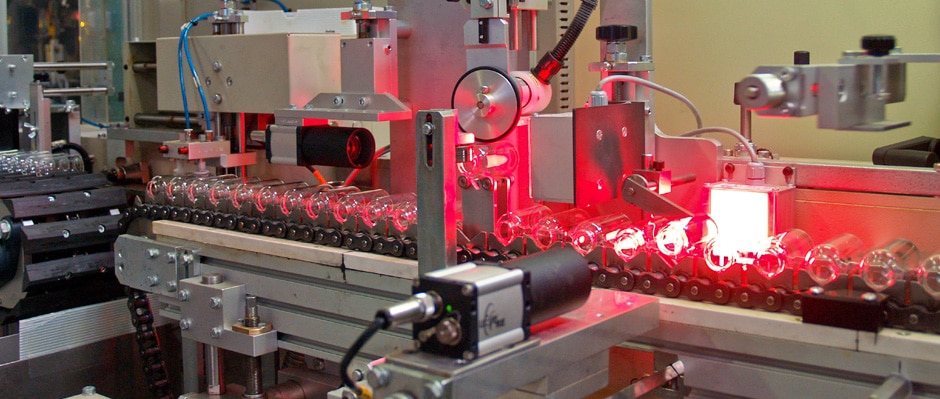

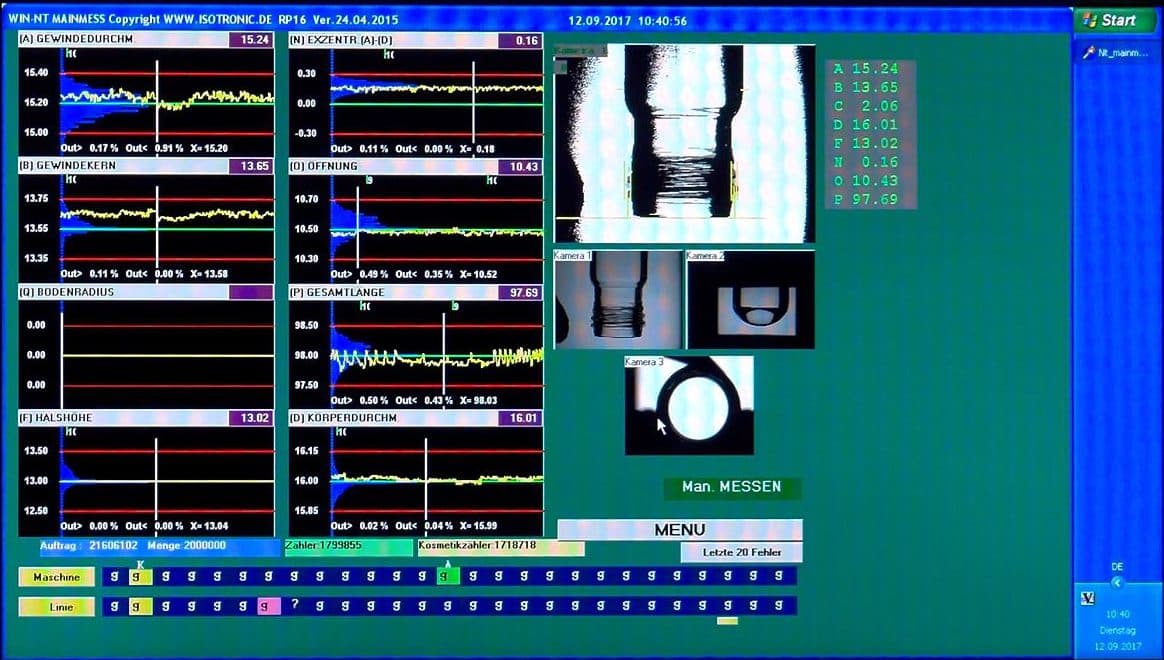

Optoelectronic measurement

04

Relax the glass surface in the hardening furnace at approx. 600 ° C

05

Packaging the glass vials in the class 10.000 clean room

Qualitative aspects in manufacturing

01

Raw material

- Schott glass tubes of the 1st hydrol. class

- For safety reasons, thick glass walls in the headspace area

02

Hygienic conditions

Packaging in class 10,000 clean room

03

Optoelectronic measurement

Each produced vial is optoelectronically measured using a video camera. If the vial does not meet the specifications, it will be discarded in the scrap

04

In-process controls

Manual review of specifications in specified periods during manufacturing process

05

Functional Tests

For example, the smooth running of a thread by screwing on the combination seals

06

QA controls according to DIN (EN) standards

Final inspection and incoming goods inspection

Special Services in the glass sector

01

Special Inquiries

- Regarding the technical interpretation and design of the vials

- Regarding the printing (vials with logo or special writing patch)

- With regard to the packaging of vials (additional cartons, packaging according to customer requirements)

02

Certified Vials or Vial KITs available on request

- Purity certificate for EPA vials

- HPLC and GC certified vial KITs

- LC/MS und GC/MS certified vial KITs

03

Silanized Vials and Micro-Inserts

Every standard vial and every micro insert can be silanized on request.

04

Washing and Sterilizing of vials

05

Vials with barcodes

For vials with a diameter of 11mm or more, we can mechanically attach customized barcode labels to the vial body.

06

Pre-Assembeled vials

On request, we can also supply pre-screwed or pre-crimped vials

07

Labeling

On request, we can also label the packaging units with customer-specific labels.

QUALITY & HYGIENE – THATS WHAT WE STAND FOR BY CHROMA GLOBE

Packaging of vials

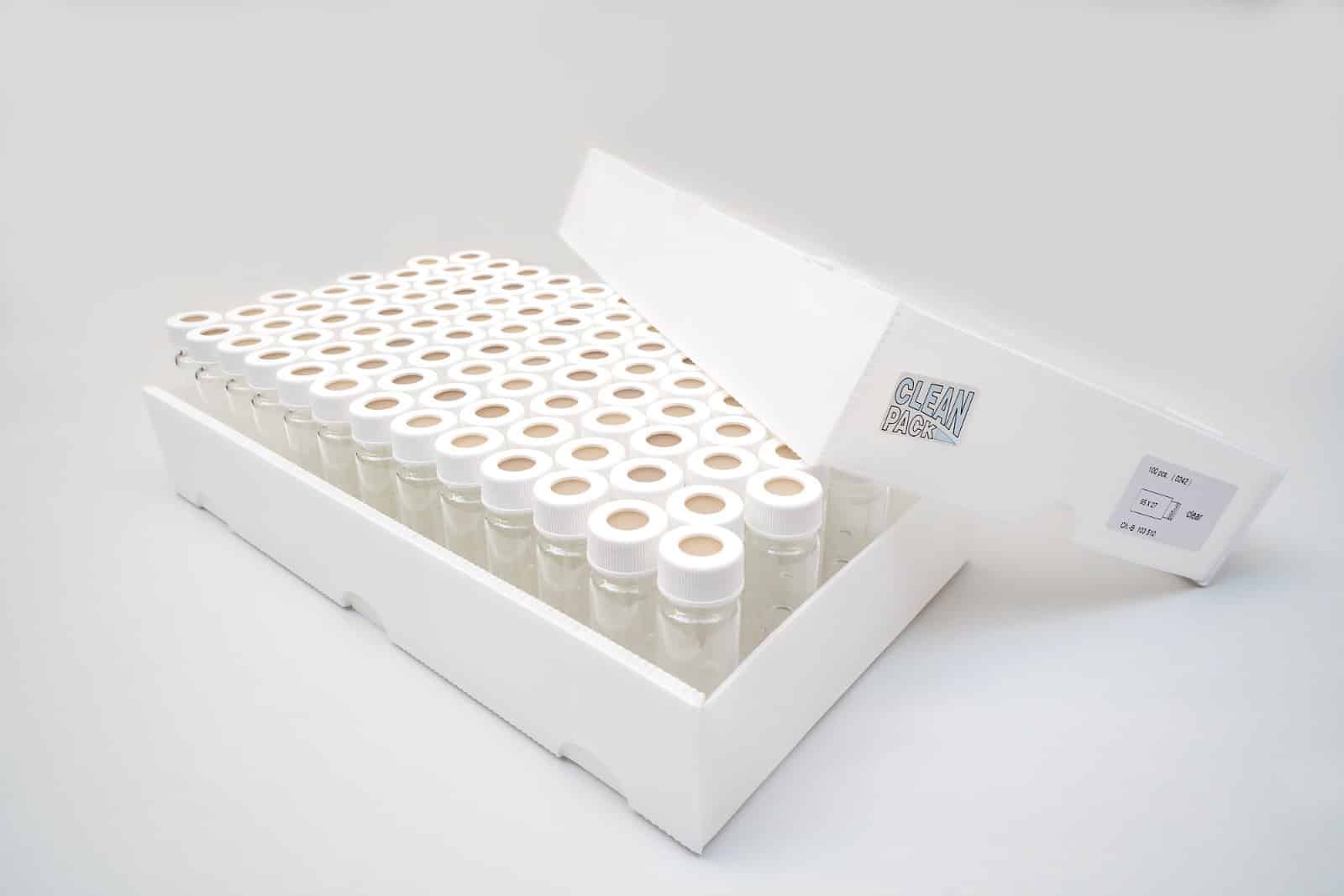

Clean room-packed vials

- Clean room-packed vials and inserts

- Tamper-evident PP boxes by shrinking the lower part

- A PP lid enables the user to close the packaging again during use

- The PP-Box has a high chemical resistance to a wide range of acids, solvents, oils and fats

- No contamination of the vials by material particles of the packaging, because PP has a high abrasion resistance

- A schematic drawing on the front of the PP boxes enables the contents to identify without opening the box

- 100% traceability function due to batch numbers on every PP Box

- Absolutely neutral packaging that enables individual resale

2in1 KITs (Convenience Pack)

- The end user only has to reorder one item

- Practical storage of vials and closures

- Resealable packaging to protect the products during consumption