Production septa and closures

Septa and closures are the most critical components in terms of the type of analysis that is performed. Therefore, high-quality raw materials and careful processing in a high-purity environment are essential to ensure product safety for a correct analysis. Careful processing is a high-purity environment that also includes avoiding any contact between people and the product, as this would result in contamination of the product by sweat and skin oil. That is why closures at CHROMA GLOBE have assembled almost exclusively fully automatically and checked by sensors at various points. The sensors check the correct lateral position of the sealing washer as well as the number of septa mounted in a closure.

Production of septa

We have several options for processing elastomers to meet your needs. We generally divide into the following groups:

Septa

for sealing vials mainly GC, HPLC & Headspace

Injection and infusion stoppers

for sealing injection and infusion bottles

GC-Septa

for sealing the injection port in gas chromatographs

Characteristics of septa

We have a wide range of options for the production of septa (sealing washers) or molded articles. Based on the following characteristics, we would like to show you how far our standard septa differ from each other and how far we can influence their distinguishing features in the course of the manufacturing process:

- Diameter -> important for the “press fit” in the cap

- We have numerous tools to manufacture punching or shaping disks in diameters from 7.8mm to 45mm. Other sizes are of course possible on request.

- Thickness -> important for needle penetration and sealing

- Total thickness of the septum

- Thickness of the PTFE coating

- Hardness -> important for the penetration of the needle, especially with thin and sensitive needles

- We can produce septa in different hardnesses for different needle types. We can influence the hardness of every material according to customer requirements. Our standard range currently includes septa hardness from 35 ° shore A – 75 ° shore A. PTFE is measured in shore D and is 53 ° shore.

- Materials-> depending on the application

- Simple, – multiple injection?

- temperatures?

- purity?

- Needle quality?

- particle formation?

- Special features -> easy penetration for thick / blunt needles (slotted, easy penetration

- Slitted / cross-slitted

Natural Rubber / TEF

RedRubber / PTFE beige RedRubber/ PTFE farblos

Butyl

Butyl/PTFE

Silikon / Aluminiumfolie

PTFE/Butyl/PTFE PTFE/Silicon/PTFE

Silikon / PTFE

PTFE

Aluminium

Viton, EPDM

- Special features – easy penetration for thick / blunt needles (slotted, easy penetration)

- Slitted/ cross-slitted

Production of Combination Seals (Closures)

Material: cap and septum

Fully automatic assembly to avoid contamination with grease and sweat

Control mechanisms

- Side-oriented feeding of the caps

- Sensor for checking the side orientation of the sealing washer (washers on the wrong side are blown back into the pot)

- A thickness gauge checks whether none, one or more sealing washers have been installed. Only closures with exactly one septum are transported into a green release container. If an error has been diagnosed, the article is conveyed into a red reject container using compressed air.

Special features

Zeropeak: Fully automatic assembly to avoid contamination with grease and sweat Closures that are marked with ZeroPeak contain an ultra-soft (needle-optimized) silicone/PTFE septum in high-purity special quality. Every batch produced is checked using GC for possible outgassing of volatile substances that could cause peaks in the consumer’s analysis. Chromatograms can be provided for a fee. We recommend these closures for critical GC analysis.

TPF–Closures (=Total Phthalat Free) Closures marked with the addition of TPF contain a high-purity phthalate-free septum, which eliminates the risk of interference peaks due to material abrasion.

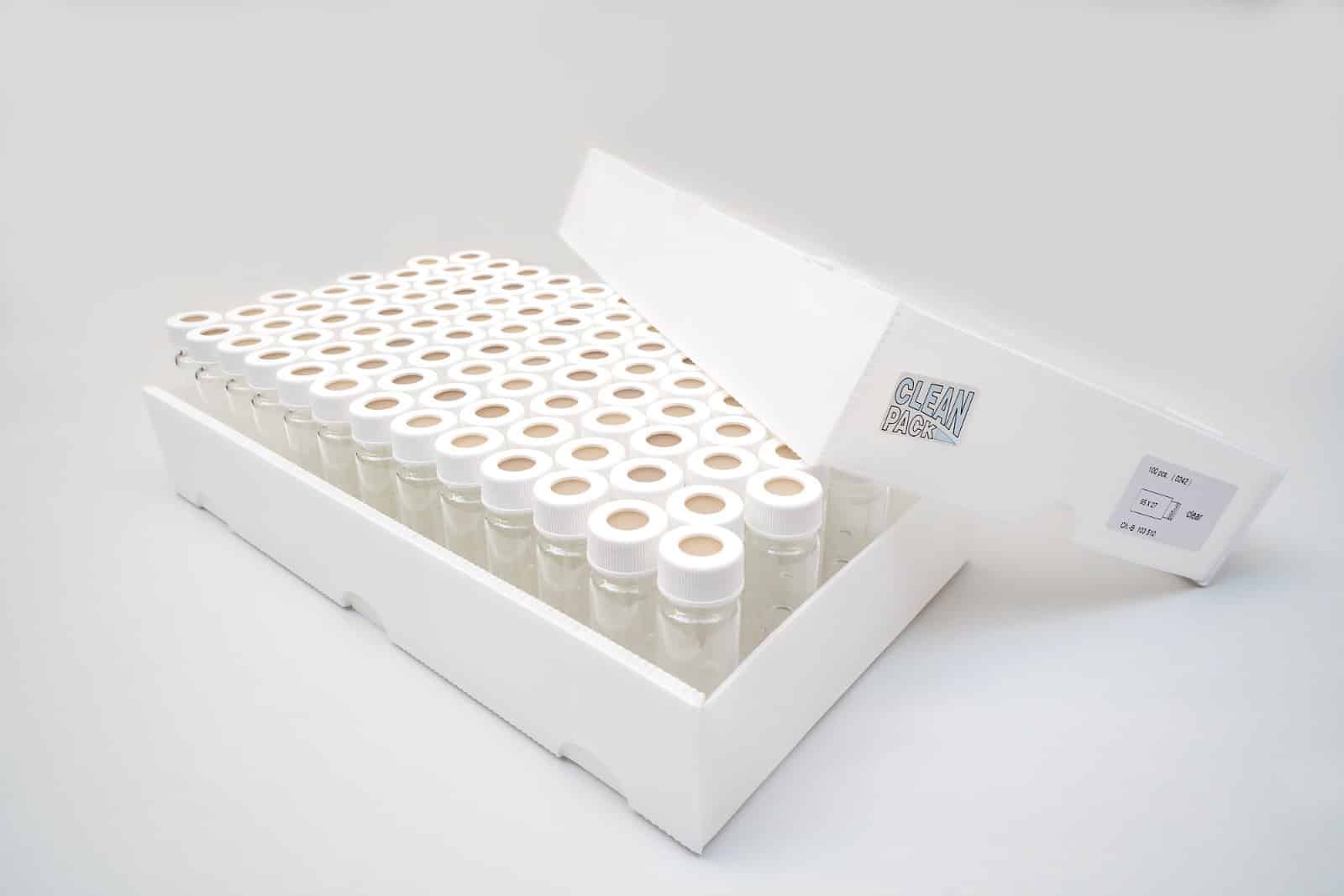

UltraClean: Closures marked with UltraClean contain a silicone/PTFE sealing septa in high-purity special quality. Every batch produced is checked using GC for possible outgassing of volatile substances that could cause peaks in the consumer’s analysis. Chromatograms can be provided for a fee. We recommend these closures for critical GC analysis.

An UltraBond locking system has the special feature that the screwcap and the sealing washer form an inseparable unit. This enables a patented manufacturing process in which the molecular structure of the contact surface of the PP. Screw cap and the sealing washer is changed so that they form a firm connection without the use of adhesives. UltraBond closures ensure:

- 100% tight fit of the sealing washer in the plastic cap; crucial, especially with larger diameters, where there is no longer a secure press fit.

- Trouble-free running on filling systems

- Autoclavability and, if desired, can be used multiple times

- Flawless injecting, even with large diameters, without the sealing washer giving way

- Excellent lockability

- Covering a wide pH range and thus a wide range of applications thanks to the PTFE coating

- Available in different durometers and sizes (ND9, ND13, ND24)

Of course, we also realize special designs based on individual customer requests with regard to the following features. Please do not hesitate to contact us.

Qualitative aspects in the area of septa and closures

01

Raw material

- Use only high-quality raw materials

02

Hygienic conditions

- Manufactured in certified, clean rooms

03

Fixed maintenance

- To avoid punching defects, flutes and counterparts are replaced or overhauled after certain stroke rates (risk of punching remnants, bulky punching disks, etc.)

04

In-process controls

- Manual review of specifications immediately after die set up, as well as in specified periods during manufacture

05

QA controls according to DIN (EN) standards

06

Final inspection and incoming goods inspection according to DIN (EN) standards

Special services in the field of septa and closures

01

Special inquiries

- Concerning the technical design and design of the cap

- Regarding the quality of the septum (UltraClean or ZeroPeak septa)

- Concerning the packaging of septa or closures (special packaging units)

- Regarding special materials

02

Labeling

- On request, we can also label the packaging units with customer-specific labels

03

Pre-sealed bottles

- On request, we can also supply pre-screwed or flanged bottles

04

Certified closures or 2in1 KITs available on request

- HPLC and GC certified 2in1 KITs

- LC / MS and GC / MS certified 2in1 KITs

QUALITY & HYGIENE – THATS WHAT WE STAND FOR BY CHROMA GLOBE

Packaging of Combination Seals (Closures)

CHROMA GLOBE counts and packs the closures produced fully automatically. The closures are gradually transported on a conveyor belt to a counting machine, where they are counted by three high-speed cameras in the case. In contrast to the weighing method, this method guarantees the consumer greater product safety concerning quantity compliance. Similar to the sample bottles, the closures are packed in tamper-evident PE bags to protect the closures from possible contamination. An analytically neutral special adhesive strip makes the bags resealable, so that end users can reseal the bags if necessary during use. The film is 60µm thick so that even heavier closures do not let the bags burst. A printed batch number allows the packaged items to be traced at any time. The transparency of the film enables the article to be easily identified.